1.How will a K&N filter affect my vehicle's fuel economy?

There is a relationship between air filter restriction and mileage. The theory behind this is simple, the harder an engine has to work to suck air through the intake tubes and air filter, the more gas gets wasted in the process. Many K&N users report an increase in their fuel economy after beginning to use our air filters. However, these experiences do not mean you will also experience a change in your mileage. We certainly understand why it is theoretically possible for a consumer to experience a mileage increase after installing a K&N air filter or intake system, however, we do not go so far as to make a general claim that our air filters and intake systems will provide an increase in mileage.

It is virtually impossible to make sweeping and general claims about mileage. Even the EPA fuel rating numbers for new cars are often not representative of the mileage you actually experience. There are many variables that affect mileage such as: tire inflation, the type of fuel, weather, elevation, the speed at which you drive, the gear in which you drive, the speed with which you accelerate, engine maintenance, excessive idling, cruise control, the grade of motor oil you use, and of course, the condition of your air filter. In short, mileage is complicated.

K&N filters are less restrictive than disposable paper or synthetic air filters and K&N Intake Systems are less restrictive than the factory installed air path. So K&N filter technology could be an important tool, when combined with other elements, to help keep mileage as high as possible.

Oh yeah, there's one more limitation imposed by science. If you take advantage of added power by driving more aggressively, you will reduce mileage. You cannot have your cake and eat it too.

2. What increase in horsepower should I expect from a K&N replacement filter?

K&N direct replacement filters which install into your vehicle's factory air box can provide an increase of between 1 and 4 horsepower. Results will vary depending on your vehicle, driving habits, load on the engine (towing for example), existing air system restriction, and other factors.

3. What increase in horsepower should I expect from a K&N air intake system?

K&N makes several different types and configurations of performance air intake systems. Depending on the year, make, and model of your vehicle, only one style of intake system may be available for that vehicle. All of our intake systems are dyno-tested and guaranteed to increase your vehicle's horsepower.

4. How often do I need to clean my K&N air filter?

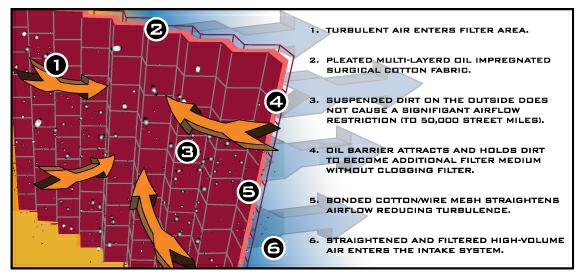

If you have not experienced a decrease in mileage or engine performance, chances are your filter is fine and does not yet need cleaning. To be more specific, the filter does not require cleaning if you can still see the wire screen on the entire air filter regardless of how dirty it may appear. When the screen is no longer visible some place on the filter, it is time to clean it. When used in normal paved road, street or highway conditions, our replacement air filters that fit in the factory air box should require cleaning every 50,000 miles and our large conical filters on an intake system should require cleaning every 100,000 miles. When used in dusty or off-road environments, our filters will require cleaning more often. We recommend that you visually inspect your filter once every 25,000 miles to determine if the screen is still visible.

5. How can I tell the size of the engine in my vehicle?

North America: Most vehicles have an emissions decal placed either on the backside of the hood, on the radiator core support, or on the air box (the box that holds the air filter in place). Your engine size should be shown on the decal (4.0L for example). If you can't find the emissions decal you may also find the engine size printed on the decal under the hood that shows your engine's belt routing. You may also write down your Vehicle Identification Number that is stamped visibly near your driver's side dashboard top and listed on your vehicle registration certificate. This number can then be entered on K&N's part search by VIN webpage to find engine size as well as products for your vehicle. You may also contact your local dealership.

Europe: Your registration documents detail your engine size and type of vehicle. However, if you do not know whether your vehicle is spi (single point injection) or mpi (multi point injection) we suggest you consult your local dealer.

6. Can a K&N filter give my engine too much air flow?

No. An engine can only draw in a certain volume of air depending on the engine's size (measured by such things as bore, stroke and number of cylinders). Vehicles are designed to accommodate large changes in air pressure so they can operate at sea level or at an altitude of 14,000 feet. Engine computers adjust the amount of fuel required as a result of changes in air pressure (density). Air filter restriction when the filter is new and especially as the filter loads with dust will result in lower air pressure and availability similar to being at a high elevation. High-flow air filters that were invented by K&N were designed to reduce the work necessary to pull air through the filter and to increase air pressure. Increased air pressure is one of the key elements in producing more power.

7. Will using a K&N direct replacement filter void my factory warranty?

It is against federal law in the United States for a manufacturer to require the use of a specific brand of air or oil filter unless it provides a replacement air or oil filter, free of charge, under the terms of the vehicle warranty. For a more thorough discussion of this law known as the Magnuson-Moss Warranty Act, see our Vehicle Warranty.

8. Will installing a K&N performance intake system void my factory warranty?

Most K&N air intake systems are warranted for 1,000,000 miles which exceeds the warranty offered on the original factory intake system.

The installation of an air intake system should not void your factory warranty. It is never a bad idea to contact your local dealership and ask them before purchasing the new K&N system whether they will object. If they tell you an air intake system will void your vehicle warranty, please contact us and we will speak with the dealership directly to clear up the misunderstanding. Another idea would be to contact a different dealer who may have a different policy since many dealership actually sell K&N intake systems.

9. Do K&N air filters come pre-oiled or must they be oiled before using?

Almost all K&N air filters come pre-oiled and ready to use. The filter oil we use is red. A new oiled filter will appear red-pink in color. Some crankcase vent air filters come unoiled, however, they come with a small packet of K&N filter oil so they can be oiled before use. There are also a limited number of filters with specialty uses which are not pre-oiled. These items will be clearly marked as unoiled. Using an unoiled K&N filter will greatly reduce the filter's efficiency and void our product warranty on filters that come pre-oiled from the factory. If you receive a filter that is packaged in its cellophane wrapper and is unoiled, contact our Customer Support department at (800) 505-3274.

10. My filter came with a tube of sealing grease. How important is it?

It is rather important. It helps to maintain a seal on an uneven air box surface. If sealing grease is unavailable, white lithium or synthetic grease will work just fine. Petroleum-based products are not recommended.

11. Are K&N filters emissions legal?

All K&N direct replacement filters are emissions legal. They perform the same function as other types of disposable filters and fit right into the factory air box. K&N's custom, universal or conical air filters are not legal for street use in California or other states that have emission control standards. However, if the intake system you are attaching a K&N cone filter to is CARB exempt, the K&N cone filter will not change that status and will be part of the exempt system. Check your local laws if you are unsure what modifications may be allowed on your vehicle.

12. Are K&N performance air intake systems emissions legal in the US?

All intake systems are legal in most states because most states do not have regulations governing them. So this question really has to do with California and other states that have emission control standards. In order for an intake system to be legal in these states, it must receive an Exemption in the form of an EO number from the California Air Resources Board (CARB). To further complicate matters CARB exemption is issued only for specific part numbers used on specific vehicles. That means a part number can be CARB exempt for some vehicle applications and not others. There is no such thing as CARB Pending. A particular part number on a particular vehicle is either exempt or not. The best way for you to determine the status of the part number you are interested in for your vehicle is to look up the intake systems available for your vehicle in our vehicle/part search engine and check for CARB exemption. If you are unsure whether CARB exemption is required for a part to be legal in your state, check with your local or state motor vehicle or emissions agency.

13. How do I clean a K&N air filter?

Use a K&N Filter Care Service Kit, available at all major auto parts stores and a low pressure nozzle-free garden hose. A filter cleaned with K&N cleaning products will ensure a lifetime of performance from your air filter. Instructions for cleaning your K&N air filter are on our Air Filter Cleaning Instructions page.

14. How much oil should I use to re-oil my filter after it is cleaned?

The best way to ensure proper oiling is to use our squeeze bottle Recharger® kit. With a squeeze bottle, you simply run a bead along the top of each pleat on both sides of the filter. If using an aerosol Recharger® kit, make one light pass over the entire filter area front and back. The oil will then be evenly absorbed throughout the rest of the cotton medium over the next several minutes. We recommend you let your filter set for 1 hour to let any excess oil run off the filter. In any event, you do not need to worry about over oiling your filter and you should make sure the oil appears fully absorbed before re-installation.

15. Can I use anything other than K&N cleaner and oil?

For best results, we recommend that you use K&N air filter oil and K&N air filter cleaner. K&N air filter oil is a special compound which forms a very efficient tacking agent that helps capture dust. Our cleaner is a non-detergent degreaser. Petroleum products such as transmission fluid and motor oil will soften and destroy the rubber sealing edges. Harsh solvents and gasoline will harden the rubber seals causing the filter to distort (shrink). A mild detergent can be used in a pinch, but care should be taken to fully rinse it out. Rinsing detergent out of a filter is similar to getting soap out of a sponge; it's not that easy to do. Always make sure the filter is dry before re-oiling.

16. Can I use compressed air to dry the filter faster?

No, this can blow the filter material right out of the wire mesh and ruin the filter. Pick a nice day to clean the filter and let it dry naturally. A low pressure air flow such as from an industrial drying machine or blow dryer will help the filter dry more quickly.

17. Should I brush the wire screen with a toothbrush to get all the "crud" off?

No, this could tear up the cotton gauze.

18. What is the micron rating and efficiency of a K&N air filter?

Air filters are not measured by micron size. As an industry standard, air filters are tested in accordance with the ISO 5011 test protocol to measure capacity (the physical amount of dust a filter can hold before cleaning is necessary) and efficiency (the filter's ability to trap and hold dust). See technical service bulletin 89-5R from the Filter Manufacturer's Council. The dust selected for the test contains a specified distribution of different particle sizes according to ISO standards.

The content of the two most commonly used types of ISO test dust for air filters is as follows:

| ISO COARSE TEST DUST | ISO FINE TEST DUST | ||

|---|---|---|---|

| Particle Size in Micrometers (Microns) | Percent by Volume (+/- 3%) | Particle Size in Micrometers (Microns) | Percent by Volume (+/- 3%) |

| 001 - 005 | 10.5% | 01 - 05 | 36.0% |

| 005 - 010 | 11.5% | 05 - 10 | 18.0% |

| 010 - 020 | 14.0% | 10 - 20 | 20.0% |

| 020 - 040 | 25.0% | 20 - 40 | 17.0% |

| 040 - 120 | 37.0% | 40 - 120 | 09.0% |

| 120 - 180 | 02.0% | ||

As has become customary in the automotive industry, we use Coarse Test Dust for gasoline engine air filters and Fine Test Dust for diesel engine air filters. This practice of using different grades of test dust developed because Diesel engines require higher levels of filtration because they operate at much higher compression and require tighter tolerances than Gasoline engines.

Our testing has demonstrated that on average, K&N replacement air filters and air intake systems have a cumulative or Full Life filtration efficiency of between 96% and 99%. Different filters test at different efficiencies due to changes in their shape, surface area and relationship to the direction of air flow through the factory air box or test housing. Like most air filters available in the USA, our filters will provide all the engine protection you need.

19. What are the air filtration requirements for my vehicle?

There is no published requirement for vehicle filtration. Car and truck owner's manuals are silent on the issue and you will find very few companies that even credibly discuss filtration efficiency. We believe this demonstrates that most air filters sold today provide adequate levels of filtration. Particularly when compared with the filtration provided by fuel and oil filters.

20. Some air filter companies tout their high filtration levels in the 99th percentile. Doesn't higher filtration mean a better air filter?

No. The quality of an air filter can only be judged by reviewing all four important characteristics. 1) Restriction while loading with dust; 2) Filtration efficiency as a percentage; 3) Dust holding capacity before the filter needs cleaning or replacement ; and 4) filter life. Any company designing an air filter must make choices about these four characteristics and how their filter will perform in each area. Generally speaking, each characteristic of an air filter has an inverse relationship to at least one of the others, meaning, as filtration efficiency goes up, restriction increases and capacity or service life decreases. So an air filter manufacturer can design an air filter to have ultra high filtration efficiency by compromising the filters restriction, capacity, and/or service life. We judge the quality of an air filter based upon the proper balance of these four essential criteria. Maximizing one at the expense of others sounds more like a marketing goal rather than an engineering goal. So the basic answer to the original question is that higher filtration is not necessarily a good thing when it comes at the expense of restriction, reusability and/or capacity. While the benefits of a filter with 99.9% filtration are unknown, the benefits of low restriction are measurable and clear. Low restriction helps an engine perform more efficiently generating more power and torque.

That would lead a reasonable person to ask what then is a safe level of filtration. This question is literally unanswered. Minimum air filter specifications are generally not called out in vehicle owners' manuals, nor will you find much published information on air filtration requirements from vehicle manufacturers. We have never seen a scientific study concluding what levels of filtration efficiency correspond to various levels of engine wear. Some large air filter companies do not even publish information on the efficiencies of the air filters they manufacture. It is K&N's opinion that both the Fine and Coarse Test Dust mixtures used in air filter testing contain such a high concentration of small particles that even filtration efficiency numbers as low as 90% may provide adequate engine protection. Remember that almost 11% of COARSE test dust is smaller than 5.5 microns (the size of a red blood cell).

The fact is that an engine is not a pristine environment. Fuel enters after passing through a fuel filter, combines with air which is ignited to explode in a pressurized chamber. The combustion is not 100% efficient and leaves residues behind that must be flushed from the engine. Engines have tolerances or measured gaps between surface areas. While there are few if any studies on engine wear, it would seem reasonable to speculate that particles less than 5.5 microns create little engine wear unless ingested at very high levels of concentration. As support for this theory, consider the filtration levels provided by fuel filters and oil filters that sometimes tout their ability to filter particles above 10 or 20 microns.

If you really want to compare two air filters, you need to know all four characteristics mentioned above. Consumers can then choose what matters most to them. But comparing two air filters with only one piece of information is like saying a bicycle is better than a car based solely on a comparison of mileage. Yes the mileage is better, but a car has a few other benefits (speed, comfort, keeps you dry in wet weather) that just may offset the mileage disadvantage.

We design air filters to provide low restriction throughout the filter's service interval. We seek the best balance between airflow and filtration recognizing they are inversely related. After nearly 40 years in business with millions of air filters sold, we have a track record you can trust and the experience that can only be earned through years of focusing on just one thing. But even our experience is not enough. We operate a fully staffed air filtration lab that operates on a year round basis with two test stands. The lab was designed by Southwest Research and is calibrated regularly to ensure our test results are reliable. This testing is an essential ingredient in verifying our air filters meet our own high standards of excellence. Making a great air filter is no accident and we are confident our air filters provide outstanding engine protection with huge air flow advantages throughout the air filter's service interval. That's why we back up our replacement air filters with both a Million Mile Warranty and our Consumer Protection Pledge.

K&N's air filtration lab tests air filters according to ISO5011 test protocol. The ISO (International Organization for Standardization) is an international organization which establishes standards used by different industries worldwide. The ISO does not establish any standards for an air filter's effectiveness; they establish standards for the testing procedures used to find air filters' capacities and efficiencies only under the fixed and chosen parameters of the test being conducted. In the case of engine air filters, the ISO5011 test ensures consistency in the procedure used to test a filter's initial restriction, initial efficiency, cumulative (full-life) efficiency, and dust holding capacity. Using a standardized test procedure and disclosing the user selected variables ensures the same test can be run anywhere around the world. Some of the requirements of the ISO5011 test procedure are that the temperature of the test lab must be maintained at 23 degrees Celsius +/- 5 degrees Celsius, and the relative humidity of the test lab must be maintained at 55% +/- 15%, for the entire duration of the test. During the test at each weighing stage (when the mass of the filter is found) the humidity can only vary +/- 2%. Also, all test dust which is fed into the air filter must be "found" after the test is completed. That means if 10 grams of test dust is fed to the filter during the test, but only 8 grams of dust is found trapped in the filter after the test, part of the ISO5011 test procedure requires that the remaining 2 grams of dust must be found. The dust could be in the air filter housing, the air duct, or the absolute filter which traps any dust that passes through the air filter, but wherever it is it must be accounted for. If any of the requirements of the ISO test procedure are not met, the test is not valid. A company's participation in testing using ISO5011 test procedures is strictly voluntary. Conducting an ISO5011 test requires a considerable investment in both time and equipment, and many air filter companies simply do not have the resources to complete an ISO test in-house. K&N views this test procedure as a valuable part of our research and development process.

21. More airflow means you are letting more dirt through, right?

No. Filtration testing measures the percentage of dust retained before the filter reaches a terminal test pressure, often 10" of restriction above initial restriction. We use airflow as a simplified term to explain a more complicated physical process. The more precise description is restriction: K&N air filters create less restriction which helps an engine run better. An engine will only use the air it needs and our air filters do not result in an engine using more air than necessary. Rather, they result in the engine experiencing less restriction. The terms airflow and restriction are inversely related. Our air filters provide either less restriction at a fixed airflow rate; or more airflow as a fixed level of restriction. In neither case is more air being used than necessary.

22. Should I install the largest K&N filter that will fit in my race vehicle?

If an existing K&N filter is large enough to provide negligible restriction, a larger than required filter will not affect the amount of air an engine can take in, however, it will lengthen the filter's service interval. A longer service interval can be an important factor when racing in dusty, dirty environments.

23. Will a K&N filter cause my vehicle's mass air sensor to fail?

No, it is both impossible and ridiculous.

It is impossible because we know that the oil treatment on our cotton is very small (usually less than 2 ounces). Once the oil is properly and evenly absorbed through the cotton, no oil will come off, even under extreme engine conditions. It is ridiculous, because no dealership or service provider has ever been able to provide us with evidence to support this "myth," and in fact, our investigations have revealed that even authorized dealerships are simply speculating and do not have the test equipment necessary to know whether the sensor has failed or why. It is even more ridiculous because some car manufacturers use and sell air filters treated with oil on a regular basis. There are also major brands of disposable air filters that are treated with oil. We all use oil for the same reason, it helps in the filtration efficiency of an air filter.

Out of the millions of air filters we sell, we only receive a handful of consumer complaints each month that a dealership or service provider has blamed a vehicle sensor repair on our product. We take each complaint very seriously and see it as an opportunity to stop a consumer from being taken advantage of.

As a result of our standing up for consumer rights and providing assistance to resolve a disagreement, we have had over 100 actual sensors sent to us by dealerships who claimed our product had caused them to fail. Microscopic, electronic and chemical testing revealed that none of the sensors were contaminated by K&N oil. What is perhaps the single biggest clue to what is going on is that over 50% of these sensors were not broken in the first place for any reason.